TYPES OF CONDUCTORS IN POWER TRANSMISSION SYSTEM

AAC- All Aluminum Conductors.

AAAC- All Aluminum Alloy Conductors.

ACSR- Aluminum Conductor Steel Reinforced.

HTLS-

High Temperature Low Sag.

In the early days of the

transmission of electric power conductors were usually copper, but aluminum

conductors have completely replaced copper for overhead lines because of the

much lower cost and lighter weight of an aluminum conductor compared with a copper

conductor of the same resistance. The fact that an aluminum conductor has a

larger diameter than a copper conductor of the same resistance is also an

advantage. With a larger diameter, the lines of electric flux originating on the

conductor will be farther apart at the conductor surface for the same voltage.

This means there is a lower voltage gradient at the conductor surface and less

tendency to ionize the air around the conductor.

Ionization produces the undesirable effect called corona.

Ionization produces the undesirable effect called corona.

Aluminum-alloy

conductors have higher tensile strength than the ordinary electrical-conductor

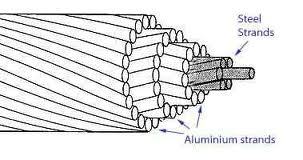

grade of aluminum. ACSR consists of a central core of steel strands surrounded

by layers of aluminum strands. ACAR has a central core of higher-strength

aluminum surrounded by layers of electrical conductor grad e aluminum.

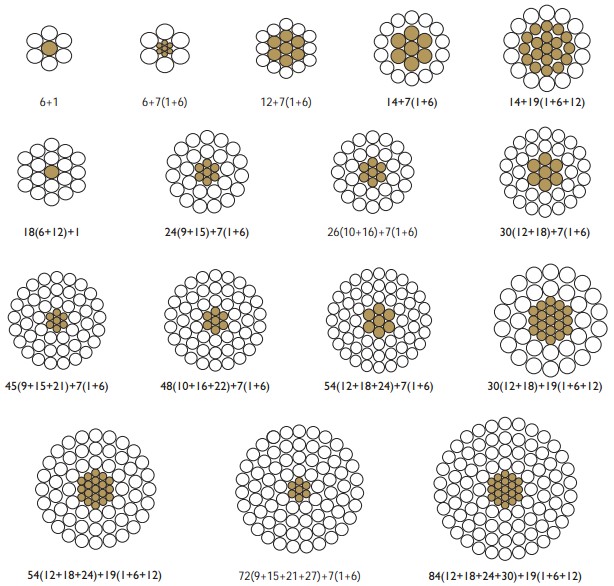

Alternate layers of wire of a stranded conductor are spiraled in opposite directions to prevent unwinding and to make the outer radius of one layer coincide with the inner radius of the next layer. Stranding provides flexibility for a large cross-sectional area. The number of strands depends on the number of layers and on whether all the strands are of the same diameter. The total number of strands in concentrically stranded cables, where the total annular space is filled with strands of uniform diameter is 7, 1 9, 37, 61, 91, or more.

Figure shows the cross section of a typical steel-reinforced aluminum cable (ACSR). The conductor shown has 7 steel strands forming a central core, around which there are two layers of aluminum strands. There are 24 aluminum strands in the two outer layers. The conductor stranding is specified as 24 Al/7 St, or simply 24/7. Various tensile strengths, current capacities, and conductor sizes are obtained by using different combinations of steel and aluminum.

1.Specification to which the finished conductor conforms: IS-398Part-II-1976

2.Purity of Aluminium Rods: 99.5% Minimum

3.Percentages of Carbon in steel wire/rods: 0.50 to 0.85 (Preferably 0.65%)

4.Purity of Zinc: 99.95%

Alternate layers of wire of a stranded conductor are spiraled in opposite directions to prevent unwinding and to make the outer radius of one layer coincide with the inner radius of the next layer. Stranding provides flexibility for a large cross-sectional area. The number of strands depends on the number of layers and on whether all the strands are of the same diameter. The total number of strands in concentrically stranded cables, where the total annular space is filled with strands of uniform diameter is 7, 1 9, 37, 61, 91, or more.

Figure shows the cross section of a typical steel-reinforced aluminum cable (ACSR). The conductor shown has 7 steel strands forming a central core, around which there are two layers of aluminum strands. There are 24 aluminum strands in the two outer layers. The conductor stranding is specified as 24 Al/7 St, or simply 24/7. Various tensile strengths, current capacities, and conductor sizes are obtained by using different combinations of steel and aluminum.

TECHNICAL PARTICULARS OF ACSR 'PANTHER', 'ZEBRA' & 'MOOSE' CONDUCTOR.

1.Specification to which the finished conductor conforms: IS-398Part-II-1976

2.Purity of Aluminium Rods: 99.5% Minimum

3.Percentages of Carbon in steel wire/rods: 0.50 to 0.85 (Preferably 0.65%)

4.Purity of Zinc: 99.95%

| Unit | ACSR 'Panther' | ACSR 'Zebra' | ACSR 'Moose' | ||

| 5. | Particulars of Aluminium strands | ||||

| i) | Diameter | ||||

| a) Standard | mm | 3.00 | 3.18 | 3.53 | |

| b) Maximum | mm | 3.03 | 3.16 | 3.55 | |

| c) Minimum | mm | 2.97 | 2.19 | 3.51 | |

| ii) | Cross sectional area of standard diameter wire | mm2 | 7.069 | 7.942 | 9.787 |

| iii) | Weight per Km | ||||

| a) Standard | Kg | 19.11 | 21.47 | 26.45 | |

| b) Maximum | Kg | ||||

| c) Minimum | Kg | ||||

| iv) | Minimum breaking load | ||||

| a) Before stranding | KN | 1.17 | 1.29 | 1.57 | |

| b) After stranding | KN | 1.11 | 1.23 | 1.49 | |

| v) | Maximum D.C. resistance at 200C | Ohm/Km | 4.107 | 3.651 | 2.921 |

| vi) | Joints in strands of 12 wire Aluminium layer if any | No joint | No joint | No joint | |

| 6. | Particulars of Steel strands | ||||

| i) | Diameter | ||||

| a) Standard | mm | 3.00 | 3.18 | 3.53 | |

| b) Maximum | mm | 3.06 | 3.21 | 3.60 | |

| c) Minimum | mm | 2.94 | 3.14 | 3.46 | |

| ii) | Cross sectional area of standard diameter wire | mm2 | 7.069 | 7.942 | 9.787 |

| iii) | Weight per Km | ||||

| a) Standard | mm | 55.13 | 61.95 | 76.34 | |

| b) Maximum | mm | 57.36 | 63.12 | 79.39 | |

| c) Minimum | mm | 52.95 | 60.40 | 73.33 | |

| iv) | Minimum breaking load | ||||

| a) Before stranding | KN | 9.29 | 10.43 | 12.85 | |

| b) After stranding | KN | 8.83 | 9.91 | 12.22 | |

| v) | Elongation of 200 mm length on breaking | % | 4 | 4 | 4 |

| vi) | Coating of steel core | ||||

| a) Quality of Zinc | 99.95% purity | 99.95% purity | As per IS: 209-1979 | ||

| b) Process of galvanising | Hot Dip | Hot Dip | Hot Dip | ||

| c) Minimum weight of coating | gm/m2 | 240 | 250 | 260 | |

| d) Minimum no of dips of one minute duration which the strand can withstand (under preace test) | Nos. | 3 | 3 | 3 | |

| 7. | Particulars of Complete Conductor | ||||

| i) | Code words, if any | ACSR 'Panther' | ACSR 'Zebra' | ACSR 'Moose' | |

| ii) | Copper equivalent Area | mm2 | 310 | 260 | 325 |

| iii) | Nominal aluminium area | mm2 | 200 | 420 | 520 |

| iv) | Sectional area of aluminium | mm2 | 212.10 | 428.91 | 528.50 |

| v) | Total sectional area | mm2 | 261.50 | 484.50 | 597.00 |

| vi) | Overall diameter | mm | 21.00 | 28.62 | 31.77 |

| vii) | Stranding, lay and wire diameter | ||||

| a) Aluminium | mm | 30/3.00 Right Hand lay | 54/3.18 | 54/3.53 | |

| b) Steel | mm | 7/3.00 | 7/3.18 | 7/3.53 | |

| viii) | Lay ratio | Min. mMaxm | |||

| a) Steel core | |||||

| i) 6 wire Layer | Max. | 28 | 28 | 28 | |

| Min. | 13 | 13 | 16 | ||

| b) Aluminium | |||||

| i) 12 Wire Ist Layer | Max. | 16 | 15 | 14 | |

| Min. | 10 | 10 | 12 | ||

| ii) 18 Wire IInd layer | Max. | 14 | 14 | 13 | |

| Min. | 10 | 10 | 11 | ||

| iii) 24 Wire IIIrd Layer | Max. | - | 12 | 12 | |

| Min. | - | 10 | 10 | ||

| x) | Approximate calculated breaking load | KN | 89.67 | 130.32 | 159.60 |

| xi) | Final modules of Elasticity (Practical) | GN/m2 | 80 | 69 | 69 |

| xii) | Coefficient of linear expansion | Per0C | 17.8x10-6 | 193x10-6 | 19.35x10-6 |

| xiii) | Approximate total weight per Km | ||||

| a) Steel Section | Kg | 388.00 | 437.00 | 537.00 | |

| b) Aluminium Section | Kg | 586.00 | 1184.00 | 1461.00 | |

| c) ACSR Composite | Kg | 974.00 | 1621.00 | 1998.00 | |

| xiv) | Calculated D.C. resistance at 200C (Maximum) | Ohm/Km | 0.1390 | 0.06885 | 0.25595 |

| xv) | Standard length of conductor (with tolerance, if any) | Metres | 1500+5% | 1500+5% | 1500+5% |

| xvi) | Number of standard length in one reel (drum) | Nos | One | One | One |

| xvii) | Random lengths (Maximum percentage of the lengths ordered) | % | 10 | 10 | 10 |

No comments :

Post a Comment